PROJECT 51: Carburetors. The MG (and many other British

sports cars of the period) used a pair of side-draft carburetors made by SU.

They were (and are) notoriously finicky to get set up and balanced, and to the

American mind, are far more complex than a carburetor needs to be. There are

aftermarket kits that replace them with a "normal" downdraft carb,

but obviously, I can't go there. So, I am rebuilding the 69-year-old originals.

Over time (especially when the car isn't even started for many

years) the seals and gaskets dry out and crack, but there aren't too many

moving parts to wear out. The major wear items are the fuel-metering needle and

the throttle-plate shaft.

The metering needle is a long, small diameter pin that is

slightly tapered from one end to the other. It fits inside a jet body with a

hole that is only a tiny bit larger than the big end of the pin. This is where

the fuel is "metered" into the intake air. The farther the tapered

pin is drawn out of the jet, the more fuel is delivered.

Surprisingly, the pins and jets in my carbs had been adjusted

properly and showed almost no signs of wear. But since the rebuild kits came

with new jets, I decided to replace the old needles, as well. The

"universal" kit does not come with needles because there are

"standard," "lean," and "rich" versions to choose

from.

The throttle-plate shafts were a different story. Both the

shafts and the holes in the throttle bodies in which they turn showed plenty of

wear! There is supposed to be about .001" of clearance between the shaft

and the hole; mine had more than .008". That creates a leak-path for air

that makes setting a smooth idle almost impossible.

The kits come with new shafts and a set of bushings to make

the holes the right size. Installing the bushings requires machining both sides

of the throttle body castings (you can't do both from one side), and while I

was figuring out how I was going to fixture the parts in my mill to get both

bushings perfectly in line, I did some Internet searching to see what others

might have come up with.

Several times I saw the name "Bob Johnson in Claremore, OK"

pop up as being THE guy to send your SU carbs to if you wanted them rebuilt. I

e-mailed him and asked what he would charge to just install the bushings. He

replied $50 total for two bushings in both bodies. No brainer! The bodies and

bushings were in the mail the next morning.

While waiting for those parts to come back, I cleaned and

polished the rest of the components, and I also sent the exhaust manifold out

to be ceramic coated. It should never rust or discolor, again.

The assembly of the carbs is intricate and a bit complicated,

and the instructions that came with the rebuild kits are not the best I've ever

seen. Because the kits will service several different models of SU carbs, there

are some extra washers and gaskets … and they don't bother to tell you that.

There is also an illustration that shows a "piston return spring"

that was missing from both of my carbs. While cursing Brutus, yet again, I did some

digging on the Internet, and I found that that spring wasn't used in the early

TD carbs. (While Brutus was blameless for the spring, he did manage to lose

some of the original screws and replaced them with whatever he could find.)

Between the rebuild-kit instructions, the photos that I took

during disassembly, and some better cut-away and exploded views from the

Internet, I was able fit all the puzzle pieces back together to factory specs.

I mounted the finished carbs and the air-cleaner to the

engine for photos, but they will come back off before the engine gets mounted

in the frame, to make sure they don't get damaged.

|

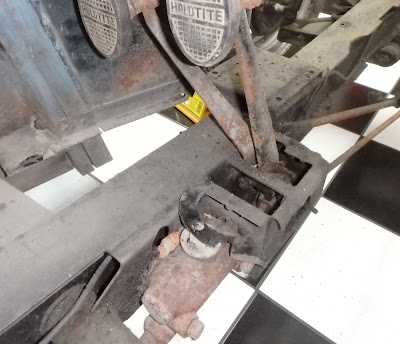

| Before the engine removed from the car. |

|

| I took plenty of before photos. |

|

| Before and after polishing. |

|

| Rebuild kits and the carb parts. (Throttle bodies are at the shop.) |

|

| After with ceramic-coated exhaust manifold. |

|

| Shown with the restored air cleaner. |